Construction - Advantages and disadvantages of Globe valves

All types of ship machines and parts get worn out due to continuous usage and working. Proper maintenance and routine checks are necessary to ensure that the machines work for a longer time. In this article, we will have a look at various reasons that lead to cylinder liner wear and how it can be minimised.

Reasons for Cylinder Liner Wear

The wear in the cylinder liner is mainly because of following reasons:

1) Due to friction.

2) Due to corrosion.

3) Abrasion

4) Scuffing or Adhesion

2) Due to corrosion.

3) Abrasion

4) Scuffing or Adhesion

Frictional Wear:

Whenever two surfaces slide over each other, friction is produced which leads to wearing down of both the surfaces. In liner wear, the surfaces are piston rings sliding over the cylinder liner. The frictional wear depends upon various factors like speed of movement between the surfaces, material involved, temperature, the load on engine, pressure, maintenance, lubrication, and combustion efficiency.

Corrosion:

The cylinder liner wear due to corrosion is caused due to these reasons:

– Burning of heavy fuel oil in the combustion space:

This happens because heavy fuel oil contains high sulfur content. During combustion, acids are formed inside the space which should be neutralised by cylinder oil which is alkaline in nature. The production of acids will be more if sulfur content is more, leading to the formation of sulphuric acid. Sulphuric acid is formed due to absorption of the condensate or moisture present inside the combustion space.

– Burning of heavy fuel oil in the combustion space:

This happens because heavy fuel oil contains high sulfur content. During combustion, acids are formed inside the space which should be neutralised by cylinder oil which is alkaline in nature. The production of acids will be more if sulfur content is more, leading to the formation of sulphuric acid. Sulphuric acid is formed due to absorption of the condensate or moisture present inside the combustion space.

– Lower combustion chamber temperature because of reduced service load:

As the low load operation of the marine engine is gaining popularity, it also leads to low temperature in the combustion chamber. If the cylinder oil quantity is not matched properly with the load, it may lead to corrosion of liner.

Acid sulfuric corrosion is found more in the lower part of the liner as the temperature of jacket water is very low. Corrosion due to sulfur will be high due to the presence of water in fuel and condensate in the air. This wear is generally seen between the quills. The wear near the quills enlarges and gives a characteristic of the clover leaf shape to the wear pattern. This phenomenon is called clover leafing.

Abrasion

This type of cylinder liner wear is due to the hard particles present and formed during combustion. Catalytic fines in the fuel, the ash formed during the combustion, metal swarf, dust and accumulated wear particles in the lube oil cause abrasive wear.

The abrasion wear rate is higher at TDC and BDC of the liner. Once the abrasive wear hits the surface, due to exposure of metal without protection, it is highly susceptible to corrosion wear too.

Adhesion or Scuffing

This is a form of local welding between the particles of piston rings and the liner surface. As the piston is moving inside the liner, the welding which has occurred breaks and leads to the formation of abrasive material. The abrasive material will increase the rate of wear of the liner. This is generally caused by insufficient lubrication due to which a large amount of heat is produced and microscopic welding of rings and liner surface takes place. Due to this type of wear the liner loses its properties to adhere cylinder oil to the surface. One more reason or this phenomenon is polishing of the surface caused by scuffing, giving liners a mirror finish.

How Can Cylinder Liner Wear be Minimised?

Cylinder wear can be minimised by carrying out the following steps:

1) By avoiding any ingress of water inside the liner by properly treating the fuel oil.

2) By maintaining the correct grade of cylinder oil.

3) By supplying correct feed rate with load change dependent lubrication system

4) By avoiding ingress of moisture from the charge air.

5) By maintaining proper jacket water temperature.

6) By supplying good quality purified fuel oil inside the combustion chamber

7) By properly maintaining the fuel injector and fuel system for correct atomization and injection of fuel inside the chamber

8) By doing regular scavenge port inspection for early detection of piston ring wear and liner surface wear

2) By maintaining the correct grade of cylinder oil.

3) By supplying correct feed rate with load change dependent lubrication system

4) By avoiding ingress of moisture from the charge air.

5) By maintaining proper jacket water temperature.

6) By supplying good quality purified fuel oil inside the combustion chamber

7) By properly maintaining the fuel injector and fuel system for correct atomization and injection of fuel inside the chamber

8) By doing regular scavenge port inspection for early detection of piston ring wear and liner surface wear

9) By doing proper running in of new liner as prescribed by the engine maker

10) By honing the wear liner surface to retain oil in the small pocket avoiding scuffing and other problems

How to Measure Cylinder Liner Bore Wear?

Cylinder liner ovality has to be gauged at regular intervals as specified in the maintenance manual. The records of gauging are kept for each cylinder and wear rate is calculated.

Procedure:

1. After engine is shut down and cooled, open the cylinder head and remove the piston

2. Cover the stuffing box hole to avoid debris falling inside crankcase

3. Remove the liner ring and clean the carbon deposits from top surface of the liner

4. Insert a ladder and carefully inspect the liner surface before gauging

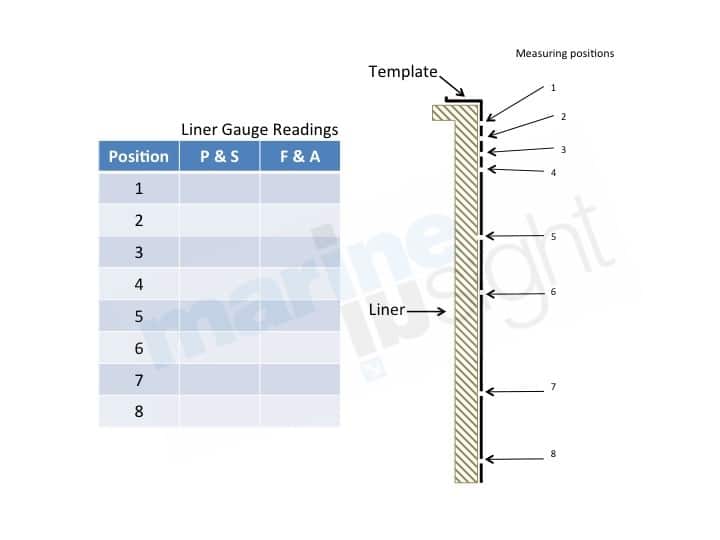

5. The cylinder liner wear is measured by a standard template, which consists of strategically positioned holes, wherein the micrometer is placed and the readings are taken

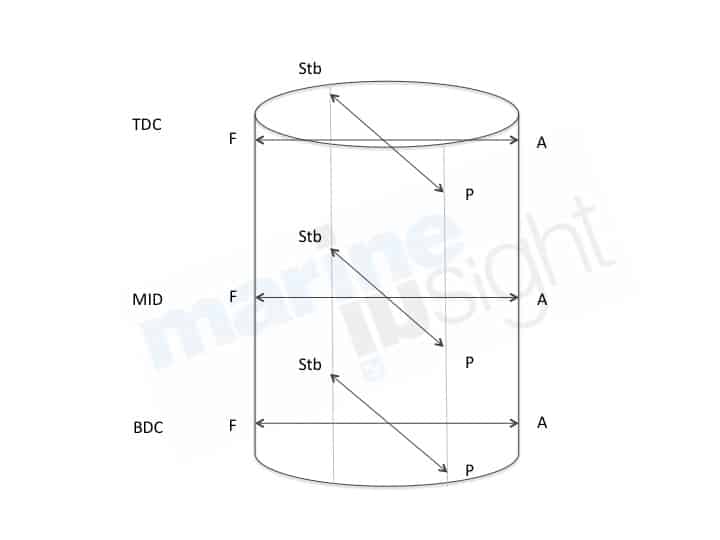

6. The readings are taken for both port starboard and forward aft positions. This is done because the wear is not same in both direction and the cylinder liner ovality is checked.

2. Cover the stuffing box hole to avoid debris falling inside crankcase

3. Remove the liner ring and clean the carbon deposits from top surface of the liner

4. Insert a ladder and carefully inspect the liner surface before gauging

5. The cylinder liner wear is measured by a standard template, which consists of strategically positioned holes, wherein the micrometer is placed and the readings are taken

6. The readings are taken for both port starboard and forward aft positions. This is done because the wear is not same in both direction and the cylinder liner ovality is checked.

A liner diameter measuring instrument ( a type of micrometer) along with a standard template rod is used to measure liner dimensions. Generally while taking the measurement the temperature of the liner and micrometer should be kept at the same temperature.

If the temperature exceeds than that of the liner or vice versa then the readings have to be corrected by multiplying the value with the correction factor and deducting the value obtained from the reading taken. The reading obtained at the end will be the correct reading.

The wear rate will be different inside the liner. The wear will be more in the top one-third part as combustion takes place there and temperatures and pressure are also very high at the top.

How to Calculate Cylinder Liner Wear Rate and Ovality?

For calculating the cylinder liner wear rate, the current reading is compared with the last taken reading. Suppose, for a liner of 800 mm bore, the position 1 latest reading (for P-S) comes out to be 841.81. The last recorded reading for position 1 (P-S) is 841.45. Hence the wear for this position in P-S direction is 0.36.

Now the position 1 latest reading (for F-A) comes out to be 841.78. The last recorded reading for position 1 (F-A) is 841.45. Hence the wear for this position in F-A direction is 0.33.

To calculate the ovality, the F-A wear rate is deducted from P-S wear rate, which will be 0.03.

Similarly, cylinder liner wear rate and cylinder liner ovality for all positions are calculated in a similar manner.

An approximate normal cylinder liner wear rate is about 0.1 mm per 1000 running hours. The wear rate increases if the engine is overloaded. Generally, the liner has to be replaced when the cylinder liner wear rate is about 0.6-0.8% of the bore diameter or as per the manufacturer’s recommendation

RSS Feed

RSS Feed Twitter

Twitter 2:05 AM

2:05 AM

Around the world

Around the world

Posted in

Posted in

0 comments:

Post a Comment